If, during the process of acceptance, installation, adjustment or testing of purchased equipment, damage or malfunctions are identified, they can be documented in a report on identified equipment defects (form OS-16). Defects that were discovered during acceptance can be reflected in the equipment receipt certificate (OS-14). Typically, this document records deficiencies that can be detected during an external examination. If at this stage no faults or damage are detected, the equipment is transferred for installation. At the stage of installation and assembly of equipment, defects that impede operation may be identified that are not noticeable during external inspection; they must be documented in a report.

Application of OS-16

This document has a unified form. OS-16 was approved by Resolution of the State Statistics Committee of Russia dated January 21, 2003 No. 7. The form is not mandatory for use: an organization can independently develop a report form, for example, using this form as a sample, supplementing it with the necessary ones or vice versa, removing unnecessary details. The organization may also decide to use the approved Form OS-16. We will provide a unified form of the form and a sample of how to fill it out at the end of the article.

Depending on which forms the organization decides to use, you can either determine your own procedure for filling them out, or follow the instructions that apply to the unified forms. If you decide to use the established forms of unified primary documents, you should apply a filling procedure that meets the requirements of the instructions for them: some information on filling out the OS-16 form can be found in the instructions approved by Resolution of the State Statistics Committee of Russia dated January 21, 2003 No. 7.

Requirements for the composition of the inspection commission

The expert commission for carrying out defect detection is appointed by the head of the organization (the owner of the asset) by order. The commission must include:

- Representatives of the organization that owns the asset: technical specialists, workers who directly use the inspected object and identified the defect, representatives of accounting and administration (the owner), quality control department employees and other employees if necessary.

- Representatives of interested parties: suppliers, buyers, contractors, transporters, manufacturers, specialists from repair organizations and other interested parties.

- Experts. It is advisable to involve third-party, independent specialists.

In the work of the commission, a material person is necessarily involved, in charge of the object being examined. The composition of the commission largely depends on the purpose of drawing up the DA and is individual in nature. If it is planned to file a claim in the future, then the participation of representatives of the defendants is mandatory. If the issue of a technical breakdown is being resolved, then often it is enough to involve specialists from your organization (without outside participation).

The absence of representatives of the interested party may lead to the recognition of the results of the commission's work as invalid.

Filling out OS-16 (report of identified equipment defects)

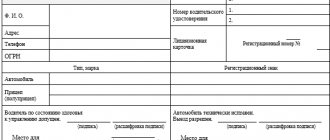

In the header of the document, general data is filled in: name of the customer organization, structural unit, form code according to OKUD, OKPO. Next, fill in the document number and the date of its preparation.

In the main part of the document, first fill in general information about the accepted equipment:

- Number and date of the act according to which the equipment was accepted for installation;

- Place where the equipment is located (exact information: address, building, workshop number);

- Name of the manufacturer, OKPO code;

- Name of the supplier organization, OKPO code;

- Shipper's name, OKPO code;

- Name of the carrier company, OKPO code;

- Name of the installation company, OKPO code.

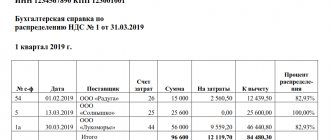

The following is a list of defects that were found in the equipment. Information about equipment that has been found to have deficiencies is presented in detail in a table of seven columns containing the following information:

- Equipment identification;

- Passport number or equipment marking;

- Brand of equipment;

- Project organization;

- Date when the equipment was manufactured;

- Date the equipment arrived;

- Defects that were found in the equipment.

Information for each piece of equipment is recorded separately in the table. Under the tabular part, the work that needs to be done to eliminate the identified defects, the performing companies that will carry out the necessary work, and the deadlines are indicated in detail.

The act is filled out by a representative of the organization installing the equipment. The document must be completed on the day the defects were discovered.

Act OS-16 is signed by a representative of the customer organization and a representative of the installation organization, indicating the position and a transcript of the signature. Further space is provided for printing and indicating the date. Further, a place is provided to indicate the signature of a representative of the manufacturer, indicating the position, transcript of the signature, and date of signature.

Each representative of the organizations that signed the document receives a copy of the act. One copy must be handed over to the installation organization, the second copy is intended for the customer, and the third for the equipment manufacturer. If necessary, additional copies can be compiled.

Form OS-16 (filling sample)

The main purpose of the defective act

A defective act (DA) is a primary accounting document that records all the shortcomings of material assets listed on the organization’s balance sheet, identified by a specially created commission. In essence, this is an expert opinion from specialists on the possibility of using equipment and inventory.

What is the document for? During operation, various equipment breakdowns occur, defects are identified, and physical wear occurs. A natural question arises: to repair or write off? It can be resolved only after a professional assessment of the condition of the equipment, for which an inspection is carried out by specialists (experts). It is in the DA that all identified shortcomings are noted and appropriate conclusions are drawn. Only on the basis of them can repair costs be incurred or material assets written off due to identified defects.

A defect report can be drawn up when accepting equipment and putting it into operation, during an inventory, during a routine inspection, or when malfunctions occur in the operation of the equipment. Based on this document, a defective list for equipment repair is drawn up or material assets are written off. If the DA is missing or drawn up incorrectly, the tax authority may not recognize the expenses incurred or write-offs in accounting. This leads to additional accrual of the tax base and penalties.

The role of the statement

The document is of an accompanying nature when identifying various types of defects. It includes:

- name and type of equipment or materials,

- damage found,

- ways to eliminate them.

This document further serves as the basis for writing an estimate and allocating funds for repair work.

Timely elimination of breakdowns and defects allows you to increase labor productivity in the organization, avoid emergency cases and situations that could lead to a threat to the life and health of employees.

It must be said that this document is not widespread. As a rule, it is used only in large enterprises, where there are a large number of structural divisions, various types of inventory, complex equipment and technical devices.

What to do if the quality is not satisfactory

As a rule, all conditions for the return of low-quality goods are specified in the contract. But sometimes the supplier is stubborn or takes too long.

If you can’t bring him to his senses, you can sue. But first you need to send an official complaint.

If this is not done, the court will not consider the case. As a rule, a claim about a defective product solves the problem; few people want to get a trial in court.

Therefore, save a sample complaint to the supplier regarding the quality of the product, it will help you cope with the problem faster.

Let's assume that there are no return conditions in the contract. In this case, the buyer has the right to write a claim for defective goods using the sample and return such delivery within 2 weeks. The rights of the buyer are specified in Article 477 of the Civil Code of the Russian Federation. The purchasing organization is required to prove that the delivered products were of poor quality before receipt.

Design rules

The act does not have an approved template, therefore it is drawn up in a free style or according to a sample accepted at the enterprise.

It can be written either on ordinary A4 paper or on the institution’s letterhead, both manually and in printed form. An indispensable requirement is that it be signed by the entire quorum, which must number at least 2 people. The number of copies of the document must be equal to the number of persons participating in the commission. Each copy of such an act has the same legal status.

If the company does not have a permanent commission in charge of checking faulty equipment, then the manager creates a commission by his own order.

The act must certainly show:

- Place and time of its registration.

- Equipment name.

- Passport parameters.

- Specifications. The more complex the device, the more detailed the description needs to be, including outlining the conditions of storage and operation.

- A detailed description of the detected breakdown. If possible, it is allowed to attach photographs of broken parts or assemblies.

- The act must be approved by the company's management.

- The date displayed on the executed deed indicates the date of its signing.

Note: If completing the form requires certain actions, the time for their execution is indicated.

To properly complete the deed, you must complete the following steps:

- The beginning of filling out the form is carried out by filling out the members of the commission indicating the position and full name. each, as well as outlining the basis for filling out the form, for example, the basis may be an order from the boss.

- Next, after filling out all the data about the device, the reason for issuing the document, a list of detected breakdowns is displayed, and the results and recommendations for further actions are summed up.

- The next part of the form records data on the implementation of actions to detect defects and eliminate them, if possible.

- The results of the actions performed are filled into a table, displaying the commission’s conclusion.

- The number of copies of the act is equal to the number of interested participants. When completing additional annexes to the main document, a link to them is filled out in the act.

- All quorum members participating in determining the reason for refusal are required to read the document and sign the document.

- The completed form is signed by the entire commission. If one of the members of the quorum does not support the conclusions, then near his painting he states his point of view.

Identifying deficiencies

There are two types of defects - obvious (visible) and hidden, that is, detected when the product, object or service begins to be used. For example, external defects, that is, chips, visible cracks on heaters installed in an apartment, can be detected during a visual inspection.

Hidden defects can only be identified after the start of the heating season, when hot water under pressure is supplied to the system.

Accordingly, acts of identifying deficiencies may be significantly distant in time from the moment of acquisition (receipt) of a product, object or provision of a service.

Actually, the final stage of expiration of the contract of sale, lease, exchange, provision of services, etc. is an act of acceptance and transfer, during which the subject of the contract passes from hand to hand.

Expert opinion

Semenov Alexander Vladimirovich

Legal consultant with 10 years of experience. Specializes in the field of civil law. Member of the Bar Association.

Since any contract includes clauses regarding quality, the transfer and acceptance certificate is intended to record not only the fulfillment of the contractual terms of the transfer, but also the quality of the transferred property.

The presence of visible defects, as a rule, is established when drawing up the acceptance certificate. Exceptions are cases of acceptance of goods in bulk, during which inspection of each item is impossible, which means that there is an option that any visible damage will become known only after a detailed inspection.

As for hidden defects, their identification takes place much later than the drawing up of the transfer and acceptance certificate, that is, in fact, after the contract is considered fulfilled.

In this case, the identification of deficiencies, as well as subsequent actions, are regulated by Part 2 of Art. 476 of the Civil Code of the Russian Federation, which establishes the buyer’s right to make claims for defects in goods during the entire warranty period or the entire shelf life (for food products).

How to properly diagnose problems

Equipment breakdowns often occur as a result of violation of operating rules.

Therefore, to prevent such circumstances, it is necessary to train a person and instruct them in the operating rules before allowing them to work on this device. True, sometimes there are situations when a person encounters a factory defect, as a result of which the equipment fails. The procedure for identifying a malfunction consists of implementing a set of measures that ensure the determination of the technical condition of the device. And to determine the type of breakdown, diagnostic devices are used, acting as troubleshooting devices. Diagnostic instruments may vary in application, difficulty of testing, testing capabilities and accuracy.

Modern diagnostic devices are equipped with electronic analysis systems capable of recording and storing diagnostic results coming from installed sensors when testing equipment.

Diagnostic equipment can be divided into the following groups:

- Scanners that diagnose the health of equipment.

- Motor testers that analyze internal combustion engines.

- Devices that test specific equipment.

The diagnostic results are documented in a corresponding document called a report:

- When equipment breaks down, a report is drawn up with the participation of several persons who are able to professionally determine the cause of the malfunction.

- The recommended form of such a form is reflected in the legislative norms.

- Some departments and ministries establish additional instructions that reflect the specific features of filling out such forms.

- It should be noted that the report of the breakdown of the device must be accompanied by a detailed report, which records the details of the malfunction, with the provision of an additional protocol on the acceptance or assignment of the device.

If defects are identified during inspection of equipment, it will be necessary to create another act - “On defects in equipment” (form OS-16).

It is also issued in accordance with regulations on the eve of sending the device for repairs, which must be carried out by the owner of the equipment. To compile this form, a unified form OS-16 is provided. At the same time, the document can be drawn up in any form with the necessary information displayed in it.

This document requires the following information to be displayed:

- Dates of purchase of the device.

- Dates of its commissioning.

- Dates of failure.

- Preventive frequency.

- The damage found and its nature.

- Person contacts.

- Device owner address.

The completed form is sent to the dealership along with the broken equipment, or to the manufacturer.

Properly executed documents ensure that problems with troubleshooting are resolved within the legal framework, with a result achieved by repairing the device, replacing it or returning money.

In what cases is it compiled?

When equipment arrives at the warehouse, an acceptance certificate is drawn up in form OS-14. A defect report can be drawn up already at this stage if the commission identifies any defects during acceptance.

When the external features of the fixed asset correspond to the declared documentation, the equipment is transferred for subsequent installation on the basis of the OS-15 act. During equipment assembly, testing and commissioning, the object may also turn out to be unsuitable for use. In this case, a report on identified defects is drawn up in form OS-16.

Depending on the culprit of the origin of the defect in the fixed asset, representatives of each company that participated in the production of the equipment and its delivery to the final destination may be involved in drawing up the report. Along with this, it is necessary to note the fact that the form can later be adjusted by the user himself.

The number of printed copies of the OS-16 act directly depends on the number of officials who signed it.

What form should I use to draw up a defective document?

The form for describing identified defects OS-16 was approved by Resolution of the State Statistics Committee No. 7 of January 21, 2003.

The use of an exclusively unified form is not specified by law.

Enterprises can develop their own form, but the document filled out according to the OS-16 form contains all the necessary fields to fill out.

The unified form of the OS-16 act is more in demand than any other form.