Any work must be safe, no matter where or who you work for, and, naturally, this responsibility of the employer must be controlled. And the control function is performed by a labor protection specialist (OSS), or a person performing these duties.

But not everyone knows what qualification requirements must be presented to a labor protection specialist, what duties must be performed, and what additional workloads are often placed on SOT workers.

We’ll also touch on a sore subject for many: calculating the number of SOTs in an organization, how an increase in staff can be justified, and much more. And if you have anything to add, write a comment and we’ll discuss it.

So, let's begin.

- Responsibility of a labor protection specialist

What does an occupational safety specialist do?

An employee responsible for occupational safety at an enterprise must have special education and regularly update their knowledge through advanced training programs. This is a serious and responsible position, since not only the enterprise, but also the employee himself may receive fines and other administrative penalties for violations of labor safety identified during the inspection.

As part of his job responsibilities, the safety specialist:

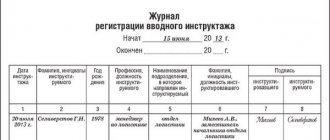

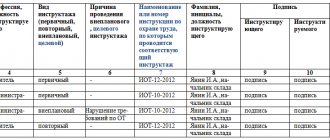

• conducts instructions and fills out occupational safety logs • determines the necessary protective equipment in hazardous industries • checks workplaces for lighting, noise levels, etc. • carries out certification of workplaces • deals with the settlement of industrial accidents • checks the technical condition of production facilities and equipment • prepares reports and much more.

After working for 1 year in an organization, you can apply for the 2nd qualification category, and after a couple of years - the 1st category. In addition to increasing your professional level and your self-esteem, changes in category also mean a salary increase. Large companies have special labor protection services. If you are a competent employee, you can become the head of such a service.

Labor functions of a specialist in the field of labor protection

| Generalized labor functions | Labor functions | ||||

| code | Name | skill level | Name | code | level (sublevel) of qualification |

| A | Implementation and maintenance of the labor protection management system | 6 | Regulatory support of the occupational safety management system | A/01.6 | 6 |

| Providing training for workers in the field of labor protection | A/02.6 | 6 | |||

| Collection, processing and transmission of information on issues of labor conditions and safety | A/03.6 | 6 | |||

| Ensuring the reduction of levels of occupational risks taking into account working conditions | A/04.6 | 6 | |||

| B | Monitoring the functioning of the occupational safety management system | 6 | Ensuring control over compliance with labor protection requirements | B/01.6 | 6 |

| Ensuring control over the state of working conditions in the workplace | B/02.6 | 6 | |||

| Ensuring investigation and recording of industrial accidents and occupational diseases | B/03.6 | 6 | |||

| C | Planning, development and improvement of the occupational safety management system | 7 | Defining goals and objectives (policies), occupational safety management processes and assessing the effectiveness of the occupational safety management system | C/01.7 | 7 |

| Distribution of powers, responsibilities, duties on labor protection issues and justification of resource provision | C/02.7 | 7 | |||

What education does an occupational safety specialist need?

Requirements for the education of workers responsible for technosphere safety are specified in the professional standard “Specialist in the field of labor protection” No. 524n dated August 4, 2014 and the Unified Qualification Directory of Positions.

In organizations employing more than 50 people, an OT service is created. Its manager must have higher education or professional retraining (additional vocational training programs of 250 hours or more) in the field of labor protection. If the company has less than 50 people, the employee responsible for the safety of work processes must undergo occupational safety training and receive a certificate of testing knowledge in the field of occupational safety.

In small companies, in order to save money, the head of the organization can deal with briefings, logs and other documentation himself. To do this, he needs to undergo 40 hours of training.

To become an occupational safety specialist, you can: • enroll in a university and receive a higher education in the field of “Technosphere Safety” • undergo professional retraining in similar programs on the basis of any higher education • undergo professional retraining in the same programs on the basis of any secondary vocational education. But you must have at least 3 years of work experience in the OT field.

Qualification Requirements

You can often hear questions about whether professional standards should be observed. The answer depends on the specific situation. Let's figure out whether it is necessary to take into account the criteria.

If work is associated with restrictions, compensation and benefits that a person can receive, then education and qualifications must correspond to information from qualification reference books, as well as the professional standard. But the labor code states that it is not always necessary to comply with professional standards. It is mandatory when required by laws or other regulatory documents. If this is not written down, then management can apply the requirements to employees at will.

Where are OT specialists trained?

In universities, private and public institutions of additional professional education, training centers. In this case, the educational institution must have a license for educational activities and separate accreditation, giving the right to provide educational services in the field of occupational safety.

In universities you will have to study from 4 to 6 years in the field of “Technosphere Safety”. In additional vocational education institutions you will be trained in 2 months or more. If you are interested in this profession, professional retraining programs called “Occupational Safety”, “Technosphere Safety”, “Safety of Technological Processes and Production” or similar options are suitable for you.

The Academy of Business and Systems Management has developed a 260-hour professional retraining program in occupational safety. The Academy is included in the Register of organizations providing services in the field of labor protection, accredited by the Ministry of Labor and Social Protection of the Russian Federation (registration number 5731 dated December 18, 2018).

Is it necessary to have on staff

Let’s first figure out whether a person responsible for labor protection and industrial safety is needed in every institution. The employer is obliged to comply with security requirements in the organization. He is obliged not only to monitor their implementation, but also to form a unit called the service of occupational safety specialists. Sometimes a special position is included in the staffing table of an enterprise. This provision, provided for in Part 1 of Art. 217 of the Labor Code of the Russian Federation, is used when the organization has more than 50 employees and carries out production activities. This activity is implemented in various economic sectors; it relates to the production of goods, performance of work, and provision of services.

Thus, the legislation in this area applies to fairly large institutions that perform a wide range of production functions.

How to get professional retraining in OT?

You can undergo retraining in labor protection on the basis of any higher or secondary vocational education. For admission, all you need is a set of documents and submitting an application for training. You don’t have to take entrance exams like at a university.

Professional retraining is an excellent option if you need to get an education in technosphere safety quickly and inexpensively. In addition, further education programs are updated much more often and faster than undergraduate programs at universities. As a rule, such updates occur every time there are changes in legislation, labor functions of employees, and requirements for their knowledge and skills. So you get the latest information.

You can learn labor safety at the employer’s expense if he is interested in you being the one to cover this front of work. In the DPO system, this is quite affordable - about 10-15 thousand rubles for a full course.

Based on the results of successful training, the educational institution is obliged to issue you a diploma of professional retraining of the established form, giving you the right to conduct professional activities in a new field.

What are skill levels 6 and 7

Depending on the authority and responsibility, the nature of skills, the nature of knowledge, and the main paths to achievement, 9 levels of qualification are distinguished. Levels 6 and 7 correspond to the following parameters:

| Level | Indicators of skill levels | Main ways to achieve qualification level | ||

| Authority and Responsibility | Nature of skills | Nature of knowledge | ||

| Level 6 | Independent activity, which involves determining the tasks of one’s own work and/or subordinates to achieve the goal Ensuring interaction between employees and related departments Responsibility for the results of work performed at the department or organization level | Development, implementation, control, evaluation and adjustment of areas of professional activity, technological or methodological solutions | Application of professional knowledge of a technological or methodological nature, including innovative ones Independent search, analysis and evaluation of professional information | Educational programs of higher education - bachelor's programs Educational programs of secondary vocational education - programs for mid-level specialists Additional programs Practical experience |

| Level 7 | Defining strategy, managing processes and activities, including innovation, with decision-making at the level of large organizations or divisions Responsibility for the results of activities of large organizations or divisions | Solving problems of development of the field of professional activity and (or) organization using a variety of methods and technologies, including innovative ones Development of new methods and technologies | Understanding the methodological foundations of professional activity Creation of new applied knowledge in a specific area Identification of sources and search for information necessary for the development of the field of professional activity and/or organization | Educational programs of higher education - master's or specialist's programs Additional professional programs Practical experience |

How to get education on labor protection remotely?

You can study to become a labor protection specialist remotely. This is convenient because... allows you to get an education without going on vacation or losing your salary. In addition, you can choose any educational institution you like, no matter where it is located.

If you have chosen the distance learning format, you may be sent training materials and assignments by email. But higher-level educational institutions that care about the quality of education will definitely offer you to study in a specially created distance learning system. You receive and complete all tasks in your personal account, and a diploma or certificate is sent by Russian Post.

At the Academy of Business and Systems Management, distance learning is available for all educational programs being implemented. Access to programs is possible from any device: smartphone, tablet, laptop. After submitting an application and paying for training in your personal account, you will learn lecture material, take tests, and complete practical assignments. During the training process you will have a personal curator. All materials for ABiUS programs are prepared by teachers and developers - current industry professionals.

How to resolve qualification issues: expert advice

If a labor protection specialist is already working at the enterprise, but is not trained according to the professional standard, then the employer has the right to remove him from work . Until the qualification level is achieved, the employee cannot work as a labor protection specialist.

During the period of professional retraining, he is suspended from work by order of the employer and without pay. The employer must offer the employee available vacancies; if there are no such vacancies, or the employee refuses the transfer and does not want to undergo professional retraining during the period of suspension from work, he must be fired.

The employer has the right, but not the obligation, to organize professional retraining at his own expense.

Article 196 of the Labor Code of the Russian Federation states that the employer determines the need for training of employees ( vocational education and vocational training ) and additional vocational education, as well as sending employees to undergo an independent qualification assessment for their own needs. Therefore, if an employee does not have the required qualifications, but is a valuable employee for the employer, for the period of professional retraining he is transferred to a position that meets his existing qualifications, and returned to the position of occupational safety specialist upon confirmation of receipt of a diploma.

How often do OT specialists need to improve their qualifications?

According to legal requirements, occupational safety specialists undergo advanced training courses and receive an occupational safety certificate at least once every 5 years. Also, once every 3 years, all employees need to undergo short-term training in occupational safety.

In special cases, for example, when your work involves monitoring work processes at a hazardous production facility, you need to undergo advanced training in industrial safety and confirm your knowledge and skills in this area every 5 years.

Technosphere safety is a very important area of work. The health and sometimes the lives of employees depend on the extent to which the enterprise complies with the standards and requirements in this area. Becoming an occupational safety specialist is worth it to responsible and methodical people who take their work seriously, monitor legislation updates and strive to keep their knowledge up to date.

Employee Responsibility

Article 419 of the Labor Code of the Russian Federation determined that those who are guilty of non-compliance with legislation and regulations, which include provisions of labor law, are subject to various types of liability:

- disciplinary;

- material;

- civil law;

- administrative;

- criminal

Thus, an employee performing functions in the safety department of an enterprise is responsible for:

- Within the scope of the job description:

- in case of poor performance or failure to fully fulfill assigned duties;

- for violation of the current legislation in the field of competence;

- for causing material damage.

- According to the Code of Administrative Offenses of the Russian Federation:

- in accordance with Chapter 5, sanctions are provided, ranging from a fine of up to 200,000 rubles to suspension of the enterprise for a period of three months.

- According to the Criminal Code of the Russian Federation:

- Art. 143 protects the standards that must be observed in all industries;

- Art. 215, 216, 217 - special, aimed at protecting standards in certain industries.

Punishment under the Criminal Code, depending on the circumstances, ranges from a fine of 400,000 rubles to imprisonment for 5 years.

How many OT engineers can work in one enterprise?

As a rule, in a small enterprise (especially if we are not talking about hazardous production), one person can calmly cope with all responsibilities related to labor protection. However, in companies with a large number of employees, the risk of emergency situations increases in proportion to the number of employees; This is why it makes sense for an employer to hire several OT engineers at once.

Indeed, in practice, ensuring decent and, most importantly, safe working conditions for each of the workers is much cheaper than constant participation in litigation and subsequent insurance payments to those injured at work.

Job description of a safety specialist

Job Descriptions

Open in WORD format

Recently, enterprises are increasingly employing not an occupational health and safety engineer, but a separate specialist who performs advisory and supervisory functions in the field of ensuring industrial safety. This position cannot be called new; rather, we can talk about a well-forgotten old one, namely: the position of a safety engineer. The unjustified reduction in the staff of enterprises in the post-perestroika period led to the fact that there were no specialists left at the enterprises who monitor the implementation of safety regulations. In turn, this has led to an increase in accidents at work, the cause of which is the technical ignorance and negligence of the workers themselves.

The “fashion” for safety specialists (not engineers) was introduced by foreign companies, which opened their production units in Russia and transferred their concept of production management. Often in foreign companies and joint ventures, the position of a safety specialist is also called a “safety consultant.” Currently, this is no longer a nominal position, which is introduced only in order to report to regulatory authorities and draw up the necessary documentation. The company wants to reduce (until completely eliminate) the likelihood of accidents at work and protect itself from unjustified payments in such cases. It also strives to eliminate even the minimal possibility of an accident at work, leading to a shutdown of production and harm to the environment.

The safety specialist performs technical and advisory work to force the existing safety system at the enterprise into compliance with current state safety standards and regulations, and also develops, in accordance with them and taking into account the characteristics of production equipment and new technologies, additional safety standards and regulations not provided for by law.

At enterprises that do not create a division (department) for labor protection and safety, but prefer to hire two specialized workers (in safety and labor protection), the safety specialist reports directly to the chief engineer or other official.

A candidate for the position of safety specialist must have at least four years of experience in production as a qualified worker or two years in a similar position, have at least a secondary technical education, and know production technology. The main requirements for him are: objectivity and impartiality, possession of teaching skills, the ability to establish and maintain constructive relationships with the team, and the ability to express himself both in written and oral form. General technical erudition, knowledge of safety documentation, and methods for investigating industrial accidents are also mandatory requirements for a safety specialist.

SPECIALIST (ENGINEER) SAFETY INSTRUCTIONS

I. General provisions

| 1. A person who has | |

| vocational (technical) education, | |

| (higher; secondary) | |

| (without presenting requirements for work experience; work experience of at least 3, 4, 5 years, etc.) | |

2. The safety specialist must know:

2.1. Legislative and regulatory legal acts, methodological materials on safety issues.

2.2. Safety principles and objectives.

2.3. System of safety standards.

2.4. Requirements for the development of safety rules and regulations at enterprises.

2.5. Basic technological processes of production of enterprise products.

2.6. Features of the operation of equipment used at the enterprise.

2.7. Rules and means of monitoring compliance of the technical condition of equipment with the requirements for safe work.

2.8. Methodology for informing workers about safety requirements.

2.9. Methods of conducting safety briefings and carrying out control activities.

2.10. Rules for providing first aid in case of accidents.

2.11. Rules for carrying out investigations of industrial accidents and recording the results of such investigations.

2.12. Fundamentals of administrative work, pedagogy and psychology.

2.13. Fundamentals of labor legislation.

2.14. Internal labor regulations.

| 2.15. | . |

3. Appointment to the position of safety specialist and dismissal from the position is made by order of the head of the enterprise upon presentation

| . |

| (chief engineer; other official) |

4. The safety specialist reports directly

| . |

| (chief engineer; other official) |

5. During the absence of a safety specialist (illness, vacation, etc.), his duties are performed by a person appointed in the prescribed manner. This person acquires the corresponding rights and is responsible for the high-quality and timely performance of the duties assigned to him.

| 6. | . |

II. Job responsibilities

Safety Specialist:

1. Consults the management of the enterprise on existing state rules and safety regulations for making changes to individual technological operations, setting up and purchasing equipment that meets safety regulations.

2. Organizes and carries out work to create a safety system at the enterprise, internal standards and safety regulations.

3. Gives an opinion on the possibility of changing the safety system adopted at the enterprise, on compliance with the safety requirements of new equipment and inventory, production operations.

4. Coordinates the work of production and technical departments of the enterprise to create and maintain a safety system.

5. Provides mandatory safety instructions.

6. Organizes safety briefings for accepted employees, employees moving to work at new production sites, new production equipment.

7. Conducts special classes on studying safety standards with management and operating personnel of the enterprise.

8. Organizes inspections, tests and technical examination of the condition of technical means, equipment, machines and mechanisms, as well as technology for performing work to determine compliance of their condition with established norms and rules, participates in their acceptance for operation or use in production.

9. Analyzes the safety situation at the enterprise, analyzes the degree of risk, develops a plan for corrective actions, sets the timing for their implementation and coordinates their implementation.

10. Monitors the implementation of instructions from state supervisory authorities and control over compliance with current safety standards and regulations, labor safety standards in the production process, as well as in projects for new and reconstructed production facilities.

11. Requires the suspension of production operations carried out in violation of the safety system at the enterprise.

12. Develops a set of measures to identify safety violations, identifies violations, analyzes them and gives instructions on how to eliminate them.

13. In the event of an accident at work:

— notifies the management of the enterprise (chief engineer, director of the enterprise) about the incident;

— organizes first medical aid for the victim and, if necessary, his delivery to a health care facility;

— takes urgent measures to prevent the development of an emergency situation and the impact of a traumatic factor on other persons;

- ensures that before the investigation of the accident begins, the situation as it was at the time of the incident is preserved (if it is impossible or inadmissible to preserve it, organizes the recording of the current situation).

14. Organizes the investigation of industrial accidents, takes part in the work of the commission, creates the necessary conditions for conducting investigations, takes part in investigations (draws up diagrams, maps of incidents, conducts surveys, takes measurements, prepares extracts from briefing logs, assists an expert (state inspector ).

15. Draws up the necessary documents for submission to regulatory authorities and executive bodies of the Federal Social Insurance Fund of Russia for insured events (if the employee is subject to insurance against industrial accidents and occupational diseases).

16. Represents the interests of the enterprise when considering accident cases by the Federal Social Insurance Fund of Russia, the state supervisory body, and the courts; gives the necessary explanations; provides the necessary documentation.

17. Monitors the adoption of new laws and regulations on safety issues.

18. Coordinates its actions with government safety agencies in order to prevent industrial, environmental and other accidents.

19. Prepares reports on the work done.

20. Performs other related duties.

| 21. | . |

III. Rights

The safety specialist has the right:

1. Give employees of the enterprise mandatory safety instructions.

2. Demand to stop production equipment and production operations that do not meet safety regulations and can lead to accidents and harm to the health of workers.

3. Sign and endorse documents within your competence.

4. Make proposals to hold department heads and other employees violating safety requirements accountable.

5. Initiate and conduct safety meetings.

6. Request from the structural divisions of the enterprise information and documents necessary to fulfill his official duties.

7. Get acquainted with the documents defining his rights and responsibilities for his position, criteria for assessing the quality of performance of official duties.

8. Submit proposals for improvement of work related to the responsibilities provided for in these instructions for consideration by management.

9. Require the management of the enterprise to provide organizational and technical conditions and prepare the established documents necessary for the performance of official duties.

| 10. | . |

IV. Responsibility

The safety specialist is responsible for:

1. For improper performance or failure to fulfill one’s job duties provided for in this job description - within the limits established by the current labor legislation of the Russian Federation.

2. For offenses committed in the course of their activities - within the limits established by the current administrative, criminal and civil legislation of the Russian Federation.

3. For causing material damage to the enterprise - within the limits established by the current labor and civil legislation of the Russian Federation.

Results

The head of an enterprise is not always able to competently organize a labor protection system that meets all legal requirements in this area.

In this he will be helped by qualified specialists and organizations, as well as methodological instructions from various departments, which provide the basis for the development of internal documents. You can find more complete information on the topic in ConsultantPlus. Free trial access to the system for 2 days.